Forage innovations

The masterminds behind Vermeer innovations

Our dedicated team continues to move the hay and forage industry forward.

At Vermeer, we like to do things a bit differently. That’s why we have two different approaches to product design. On one hand, we work to make things better, to continuously improve our machines. On the other hand, we strive to make new things, to introduce product innovations to the hay and forage industry.

So, in addition to the hardworking engineering team that focuses on bringing new features to the current lineup of hay tools, Vermeer also has a separate “Forage Innovations” engineering team. This team works every day to create new solutions and tools that don’t exist today. Their mission: To bring MORE efficiency and productivity to the hay and feed-making process.

The latest innovations

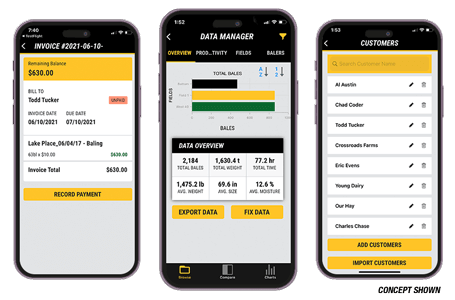

Forage Commander app

In today’s era where there are apps for everything, the Vermeer team believes there is an opportunity to have an app for making hay.

Autonomous bale mover

Nicknamed “Balehawk,” the autonomous bale mover is designed to help producers reduce the need for labor by moving bales to where you need them.

TempSense™

TempSense helps prevent bearing failure and can notify a user of needed maintenance through a suite of wireless sensors placed near critical bearings in the bale chamber.

Automated baling assistance technology

The goal of automated baling assistance technology is to help producers make the most ideal bale, in the most efficient way.

ZR5-1200 self-propelled baler

Putting up hay with the ZR5-1200 self-propelled baler delivers a productivity advantage over a traditional tractor-baler combination. Baling at up to a 2-to-1 ratio means more bales in less time. That means more time for important farm work. More time for valuable relationships with your family, friends and community. And more time for new business. The ZR5-1200 self-propelled baler is currently in production.

More innovations from Vermeer

Innovations in Vermeer balers

How to use the Vermeer Net Lift System

How to use the Vermeer Net Lift System